Site assessment

Features of ProdSphere

Enhanced Production Line Monitoring

Gain real-time insights into your production processes, identify bottlenecks, and optimize performance for improved productivity.

Reduced Downtime

Proactively detect and address issues to minimize downtime and maximize uptime, ensuring uninterrupted production.

Optimized Resource Allocation

Make data-driven decisions for efficient resource allocation, reducing waste and optimizing utilization.

Proactive Maintenance

Implement predictive maintenance strategies based on machine learning algorithms, minimizing equipment failures and optimizing maintenance schedules.

Factory performance monitoring and predictive analytics

1

![]() Live, interactive dashboard with KPI graph for each factory

Live, interactive dashboard with KPI graph for each factory

![]() Monitor performance of each production lines

Monitor performance of each production lines

![]() Collect data and improve operations with machine learning

Collect data and improve operations with machine learning

![]() Data stream processing for predictive maintenance analysis

Data stream processing for predictive maintenance analysis

![]() Predict machine failure & efficiency degradation

Predict machine failure & efficiency degradation

![]() Predictive modeling for effective maintenance scheduling

Predictive modeling for effective maintenance scheduling

![]() NLP to derive requested reports quickly

NLP to derive requested reports quickly

Anomaly diagnosis and precisions

2

![]() ML algorithms modeled for making the most accurate predictions of failures

ML algorithms modeled for making the most accurate predictions of failures

![]() Detect the misuses of a system or suspicious events

Detect the misuses of a system or suspicious events

![]() Instant notifications on mobile devices to immediately act and resolve the issues

Instant notifications on mobile devices to immediately act and resolve the issues

![]() Self-learning algorithms that continually improve production line efficiency

Self-learning algorithms that continually improve production line efficiency

Power-packed with ML and AI capabilities

3

![]() Demand forecasting and capacity planning

Demand forecasting and capacity planning

![]() Detect unexpected equipment failures symptoms

Detect unexpected equipment failures symptoms

![]() Suggest supply chain bottlenecks

Suggest supply chain bottlenecks

![]() Predictive maintenance with advanced algorithms

Predictive maintenance with advanced algorithms

![]() Digital twin to regulate production

Digital twin to regulate production

![]() Real-time demand visibility

Real-time demand visibility

Monitor the metrics that matter the most

Centralized Live Dashboard

Access a centralized dashboard that provides a holistic view of your shop floor, facilitating effective monitoring and management.

AI and IoT Integration

Harness the power of AI and IoT technologies to optimize production processes, identify inefficiencies, and enhance productivity.

Highly Trained Machine Learning Algorithms

Benefit from advanced machine learning algorithms that enable predictive maintenance, resource optimization, and process automation.

Comprehensive Industrial Automation Capabilities

Streamline your manufacturing operations with comprehensive automation features, reducing manual intervention and improving efficiency.

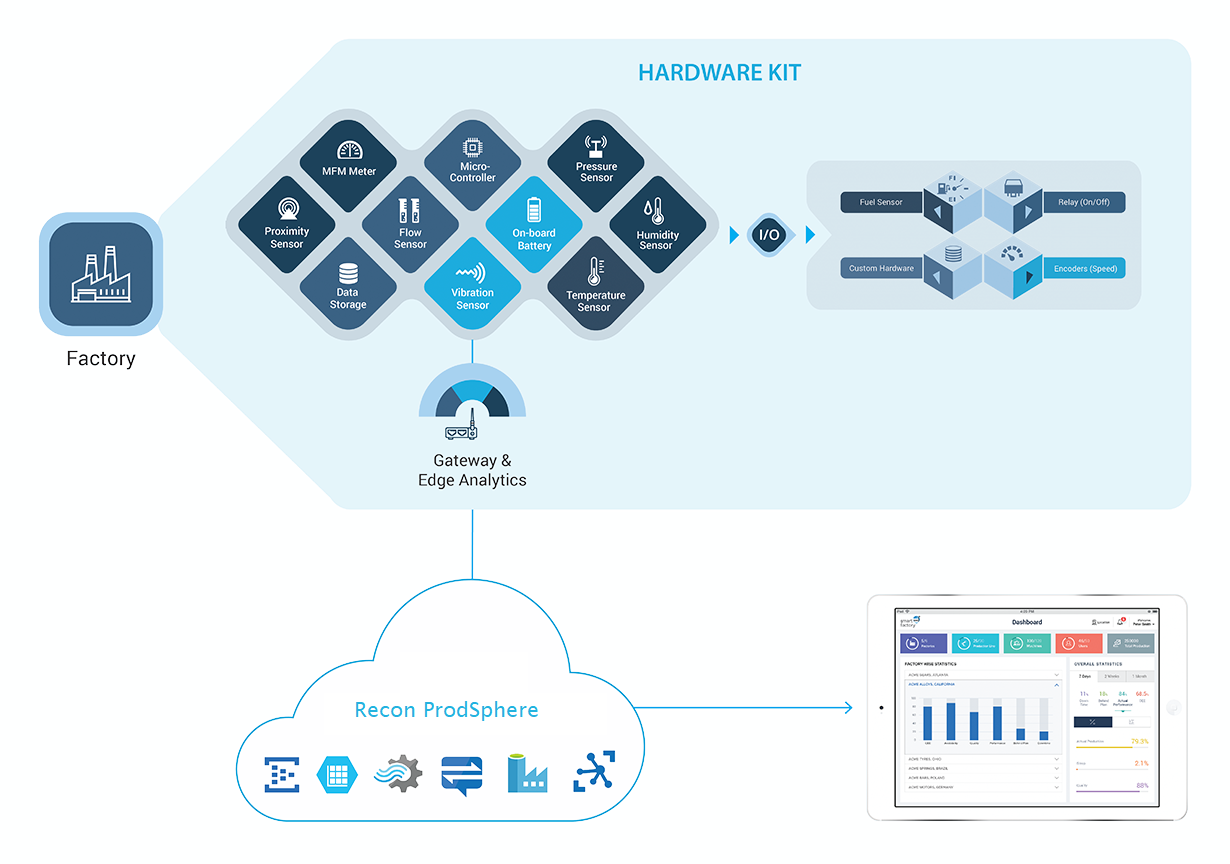

Steps to implement ProdSphere solution

1

2

Data point analysis and hardware kit finalization

3

Onboarding

4

Value realization

Frequently Asked Questions